Side-load Case Packer

Post-production for GranulesEnd of Packing Machine for Fires

Date

[Aug 28th 2021]

[Kadina Industrial]

Client

[Daily Chemical]

industry

The pharmaceutical secondary packaging market is estimated to reach US$ 41,950 million in 2023 and is projected to grow to US$ 72,010 million by 2033, with sales revenue expected to increase at a CAGR of 6.2% over the forecast period. There is a notable trend in the pharmaceutical industry towards secondary packaging solutions that enhance drug safety, security, and patient adherence. Consequently, demand for pharmaceutical secondary packaging is increasing, positioning the market for significant growth in the coming years.

Stringent regulations pose challenges for pharmaceutical secondary packaging manufacturers, delaying product introductions and increasing development costs. Consistently ensuring high quality is crucial, especially for packaging used in drug transportation and storage, where even minor defects can lead to damage or contamination. Rising costs of raw materials and production processes present additional obstacles, making competition difficult in the industry. Keeping pace with technological advancements requires significant investments in research and development, a challenge particularly for smaller manufacturers.

SAEpack is capable of addressing these challenges by offering a range of highly efficient automation solutions while ensuring pharmaceutical-grade quality and safety. We have extensive experience in designing secondary packaging solutions for pharmaceuticals. Below is a standard case example that we have selected. Customer requirements are as follows:

We choose one standard case as reference for you. Customer requirements are as follows:

Detailed Requirements

Specific Parameters

Single Box Weight

200 g

Product Dimensions

192mm x 62mm x 35mm

Outer Box Dimensions

Packing Arrangement

375mm x 335mm x 410mm

5 rows x 10 columns x 2 layers (100 boxes per box)

Tip: Carton internal space needs to be increased by 3-5mm on each side to accommodate automatic packing requirements.

Main Configuration

Suitable for boxes, cans, bottles, bags and other products, it is controlled by servo motors, occupies a small area, and is easy to maintain and intervene immediately.

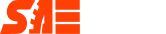

Carton sealers streamline the process of taping packages closed, saving time in medium-volume operations while ensuring consistent results.

Carton Sealer

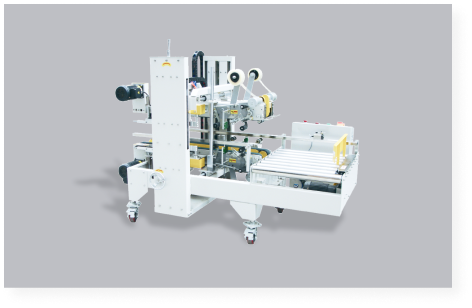

This machine automates feeding, handling, printing, sealing, and waste removal efficiently, ensuring precise operations and seamless production changes without mold adjustments.

Cartoner

Incoming Speed

60 Boxes per min

Dongguan SAE Automation Co. Ltd, is a hi-tech company who focuses on designing and manufacturingthe Automatic Packaging Line and Custo mized Automation Equipments. Our products had passed theNational Authoritative Certifcation, which had won the praises of the well-know customersdomestically and internationally

copyright © Barbecue 粤ICP备2024315457号independent Co., Ltd

@2024 Saepack

HOME

PRODUCT

HOME

EXPERICENCE

SERVICE

CONTACT US

Follow us

Contact info

Tel_1

Tel_2

Address

+86-018944711990

+86-013602366642

Henglizhen Tiantoucun

Industrial Zone 2,

Dongguan, China

sales@sae-automtion.com