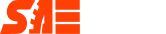

Main Configuration

Edible Oil end of line Packaging

Date

[Aug 28th 2021]

[/]

Client

[Food]

industry

The food service industry demands bulk packaging solutions that offer ease of handling and storage. The global market for edible oil packaging is projected to increase from USD 5.780 billion in 2022 to approximately USD 10.109 billion by 2032, achieving a compound annual growth rate (CAGR) of 5.8% from 2023 to 2032.

Edible oil packaging encompasses various container types and materials used for storing, protecting, and promoting edible oils. This market includes bottles, pouches, cans, and more, tailored to meet diverse consumer and manufacturing requirements. Bag-in-box and metal cans are popular choices for commercial applications. Growth in the edible oil packaging market is anticipated in emerging regions, spurred by industrial expansion and rising demand for secure and convenient packaging solutions.

SAE machines provide specialized solutions for post-production packaging of edible oil, ensuring adherence to high customer standards and complete automation. Customer requirements are as follows:

Main Sonfguration

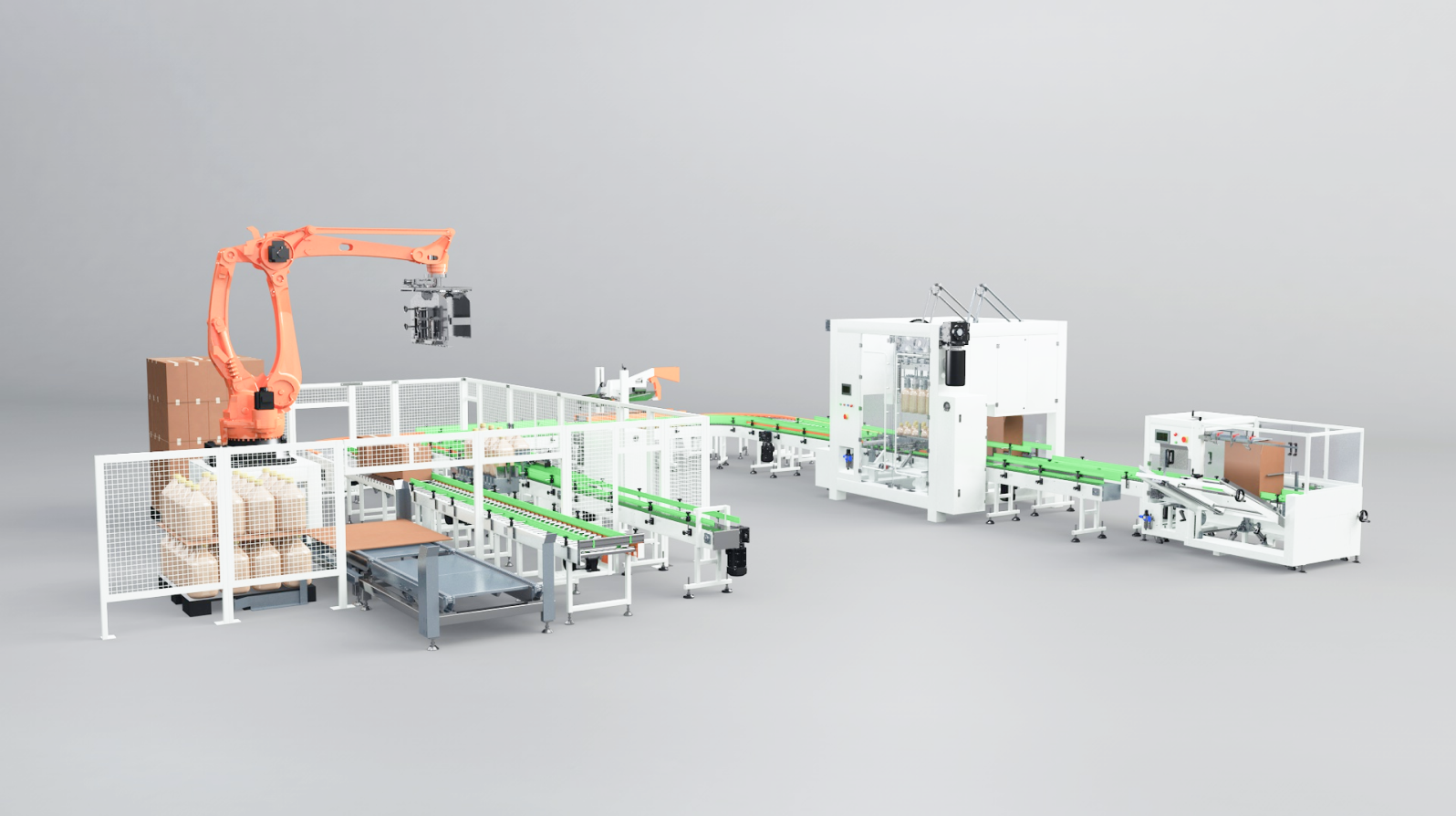

Adjusts manually for different box sizes, automates folding, taping, and ensures safety.

It efficiently forms and seals cardboard box bottoms, with quick size adjustments and high durability, mobility, and speed.

Carton Erector

The design of the equipment enables the robot to concentrate exclusively on stacking incoming products. Other tasks like dispensing pallets are automatically managed by separate equipment.

Robot Palletizer

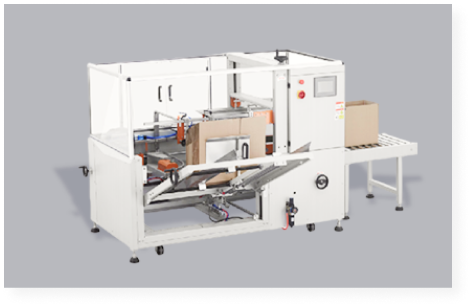

Suitable for boxes, cans, bottles, bags and other products, it is controlled by servo motors, occupies a small area, and is easy to maintain and intervene immediately.

Top-load Case Packer

Compatible with 5L and 10L automatic filling and sealing, and supports 20L products with automatic palletizing.

Main Configuration

Entire process is capable of operation without manual intervention; seamless equipment integration and

automatic docking through wired control.

Full Automation

Includes connecting conveyors between unpacking machine, packing machine, sealing machine, and palletizing machine in the entire process.

Equipment Linkage

Tip: Product dimensions and packaging speed are customizable, tailored according to customer requirements.

Dongguan SAE Automation Co. Ltd, is a hi-tech company who focuses on designing and manufacturingthe Automatic Packaging Line and Custo mized Automation Equipments. Our products had passed theNational Authoritative Certifcation, which had won the praises of the well-know customersdomestically and internationally

copyright © Barbecue 粤ICP备2024315457号independent Co., Ltd

@2024 Saepack

HOME

PRODUCT

HOME

EXPERICENCE

SERVICE

CONTACT US

Follow us

Contact info

Tel_1

Tel_2

Address

+86-018944711990

+86-013602366642

Henglizhen Tiantoucun

Industrial Zone 2,

Dongguan, China

sales@sae-automtion.com