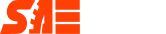

Main Configuration

Microwave Popcorn Packaging System

Date

[Aug 17th 2020]

[/]

Client

[Food]

industry

The demands of modern lifestyles have driven individuals towards convenient alternatives like microwavable dishes, replacing traditional cooked meals. These dishes require minimal preparation and can be heated in a standard microwave oven. They encompass a variety of options including shelf-stable, chilled, and frozen meals such as beef, pork, chicken, seafood, vegetarian dishes, frozen and chilled pizzas, and soups. The frozen product range extends to snacks, appetizers, and dinners featuring plant-based meat and ingredients.

Below is a standard case example that we have selected.

The unforeseen impact of COVID-19 has led to a substantial surge in the demand for microwavable foods. These products offer the advantage of prolonged nutrition retention and extended shelf life compared to fresh fruits, vegetables, and meat, thereby driving market expansion. Furthermore, the increasing digitization of retail and the rapid growth of the processed food sector are expected to create new opportunities for the microwavable foods market in the coming forecast period

.SAEpack provides specialized solutions for post-production packaging of frozen foods including microwave popcorn, ensuring adherence to high customer standards and complete automation. We choose one standard case as reference for you.

Main Sonfguration

Suitable for boxes, cans, bottles, bags and other products, it is controlled by servo motors, occupies a small area, and is easy to maintain and intervene immediately.

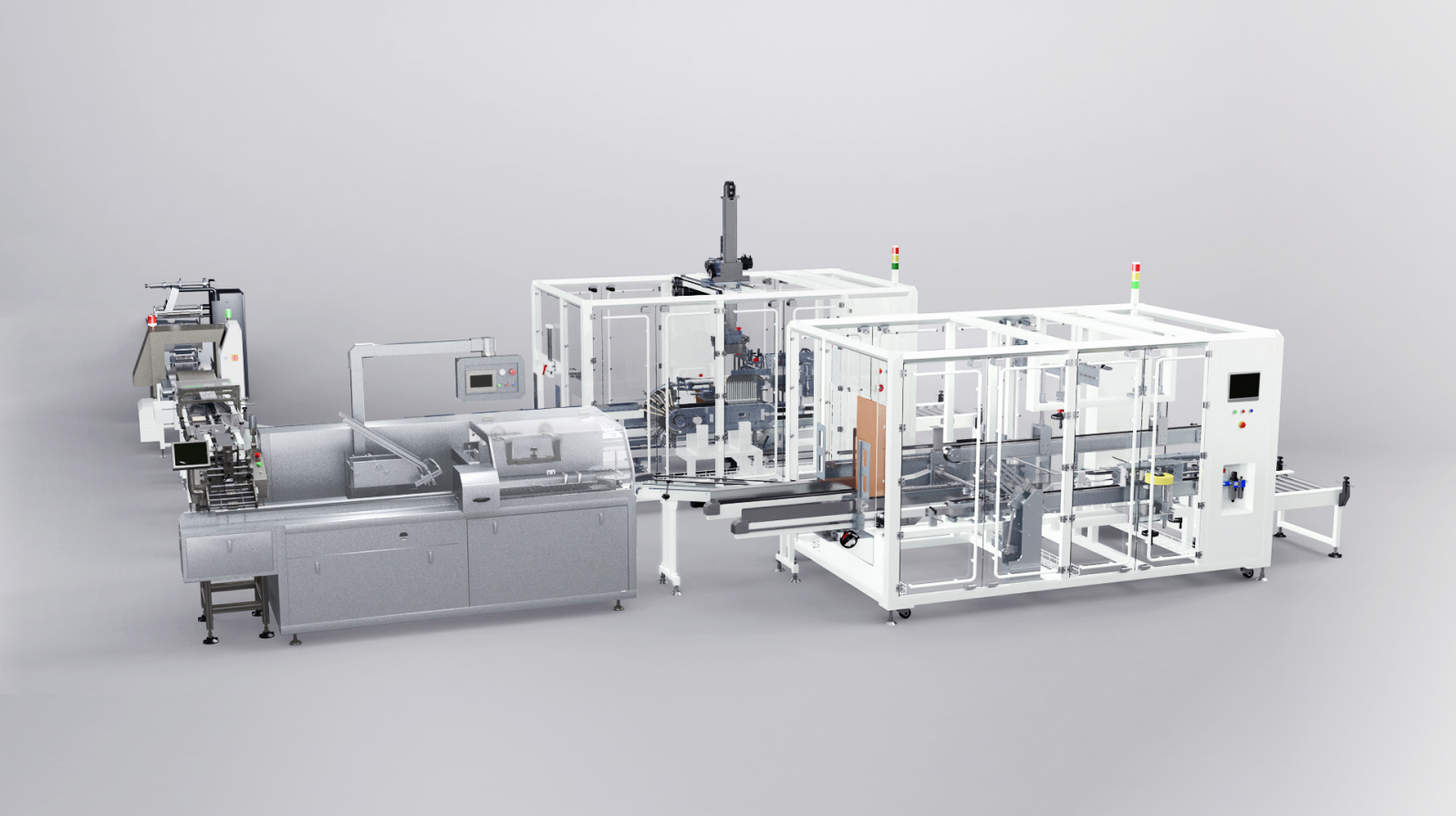

It is suitable for packaging cartons, bundles, sachets, bags and flow-packs inside corrugated shipper (RSC).

Side-load Case Packer

It minimizes film waste while offering efficient operation with automatic shutdown and alerts for film depletion or abnormalities.

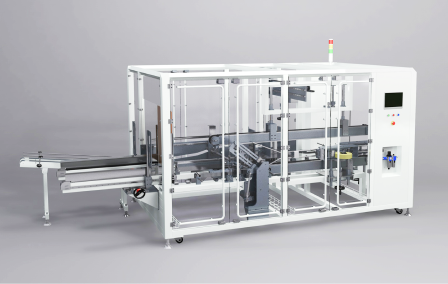

ZS-360X Packing Machine

Offers simple operation, adjustable speed control, high precision, extensive reporting capabilities, and self-learning for efficient product management.

Check Weigher

This machine features automatic product tracking with adjustable sensitivity, ensuring reliable operation and optimal accuracy tailored to varying product conditions.

Metal Detector

This machine automates feeding, handling, printing, sealing, and waste removal efficiently, ensuring precise operations and seamless production changes without mold adjustments.

Cartoner

Dongguan SAE Automation Co. Ltd, is a hi-tech company who focuses on designing and manufacturingthe Automatic Packaging Line and Custo mized Automation Equipments. Our products had passed theNational Authoritative Certifcation, which had won the praises of the well-know customersdomestically and internationally

copyright © Barbecue 粤ICP备2024315457号independent Co., Ltd

@2024 Saepack

HOME

PRODUCT

HOME

EXPERICENCE

SERVICE

CONTACT US

Follow us

Contact info

Tel_1

Tel_2

Address

+86-018944711990

+86-013602366642

Henglizhen Tiantoucun

Industrial Zone 2,

Dongguan, China

sales@sae-automtion.com