-

HOME

-

PRODUCT

- Case Packer

- Delta

- Dropdown

- Robot

- Servo

- Sideload

- Teltscospic

- Topload

- TurnableOther

- Palletizer

- cobot

- equipment

- intelligence

- palletdispenser

- robot

- Others

- cartoner

- erector

- sealer

- stapping

- weighter

- metal

-

EXPERIENCE

- kadina

- S418419

- S425426

- S413

- S433434

- S436

- S454

- S501

-

SERVICE

-

CONTACT US

-

HOME

-

PRODUCT

- Case Packer

- Delta

- Dropdown

- Robot

- Servo

- Sideload

- Teltscospic

- Topload

- TurnableOther

- Palletizer

- cobot

- equipment

- intelligence

- palletdispenser

- robot

- Others

- cartoner

- erector

- sealer

- stapping

- weighter

- metal

-

EXPERIENCE

- kadina

- S418419

- S425426

- S413

- S433434

- S436

- S454

- S501

-

SERVICE

-

CONTACT US

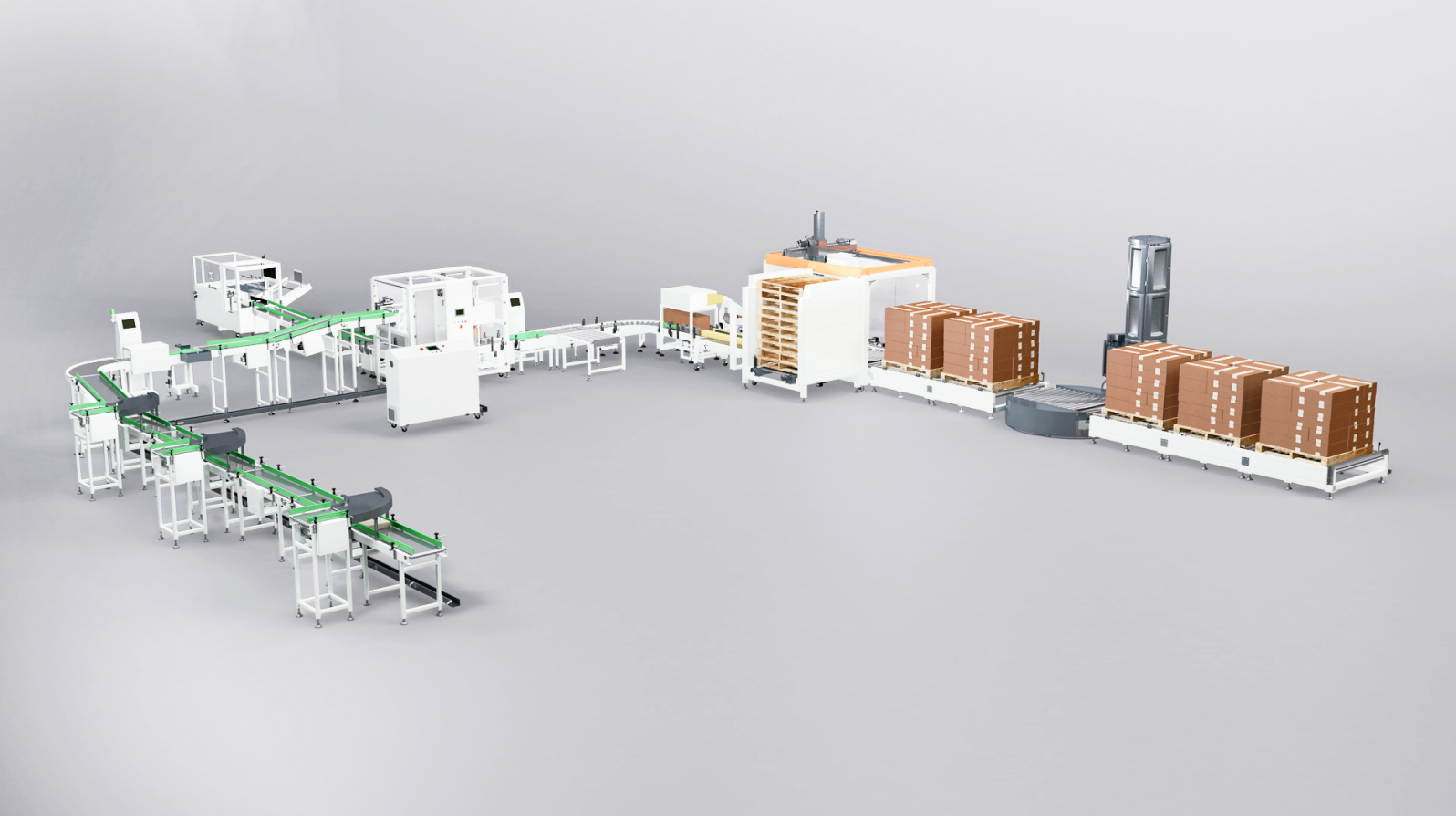

Telescopic Drop-down

Case Packer

End of Packing Machine for Fires

Date

[Aug 28th 2021]

[Kadina Industrial]

Client

[Daily Chemical]

industry

In recent years, packaging machinery enterprises have made significant strides in enhancing the quality and performance of secondary packing machines and related products through independent innovation and research. This progress has been driven by market dynamics and technological advancements. Particularly noteworthy is the growing adoption of aseptic equipment in the food sector, reflecting its increasing attractiveness and application. The expanding demand within the global food and beverage industry has consequently propelled the growth of the secondary packaging market.

Within the food and beverage sector, the frozen food market continues to expand. According to Statista, it is projected to achieve global sales of $376.95 million by 2025, with significant growth anticipated in key markets such as the US, Germany, Spain, the Netherlands, and the UK.

SAEpack offered a range of highly efficient automation solutions while ensuring daily used quality and safety. We have extensive experience in

designing secondary packaging solutions for golbal liquid. Below is a standard case example about Dishwashing liquid that we have selected. Customer requirements are as follows:

Given these developments, we choose one standard case as reference for you. Customer requirements are as follows:

Detailed Requirements

Retail Bags Sizes/1 kg

Fries bag size

370*240mm

500g

Vertical bag packaging machine speed

60 bags per min

365x305x258

Bags per carton

Carton filling speed

3*4=12 bags per carton

40-60 bags per min

17kg

455*315*180mm 470*315*175mm

Carton sizes

Tip: Product dimensions and packaging speed are customizable, tailored according to customer requirements.

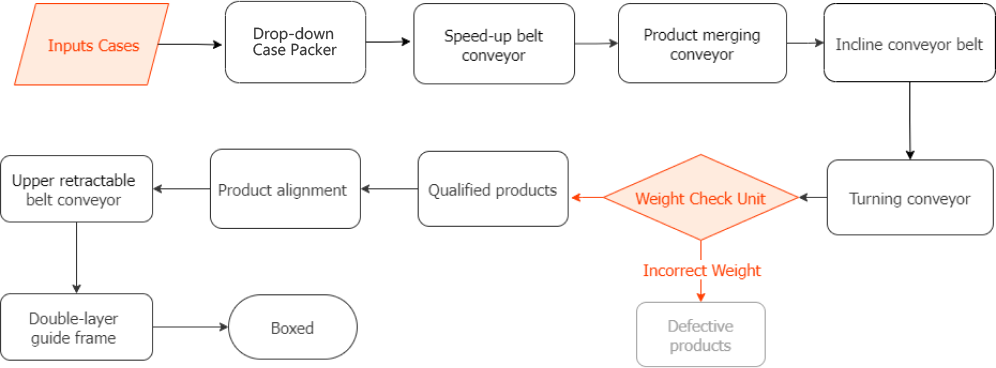

Main Configuration

Products enter a top-loading packaging machine in a single line, move through conveyors for merging, inclining, and turning, undergo metal detection and weighing, then drop into a guide frame for box packing.

Suitable for boxes, cans, bottles, bags and other products, it is controlled by servo motors, occupies a small area, and is easy to maintain and intervene immediately.

This versatile machine offers simple operation, adjustable speed control, high precision, extensive reporting capabilities, and self-learning for efficient product management.

Check Weigher

This machine features automatic product tracking with adjustable sensitivity, ensuring reliable operation and optimal accuracy tailored to varying product conditions.

Metal Detector

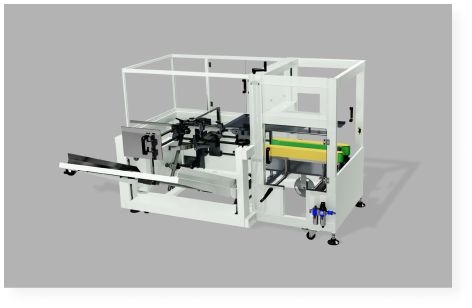

Adjust manually for different box sizes, automates folding, taping, and ensures safety.

Carton Sealer

t efficiently forms and seals cardboard box bottoms, with quick size adjustments and high durability, mobility, and speed.

Carton Erector

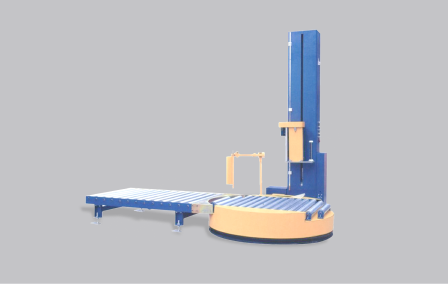

The machine uses highly elastic plastic film to wrap the items so that the fully packaged goods remain firmly placed.

Wrapping Machine

It supports packaging line operations with packaging machinery, facilitating automated pallet staging and supply distribution, significantly improving efficiency and saving on labor resources.

Pallets Dispenser

Cartons per pallet

2*4*5 = 40

Pallet stacking height

2*4*5 = 40

Food Service Size/5 kg

100 bottles per min

5 rows x 6 cloumns

5 rows x 6 cloumns

5 rows x 6 cloumns

Its infeed unit is equipped with universal vacuum grippers and capable of palletizing based on stacking patterns and pallet dimensions.

Intelligent Palletizer

Dongguan Shenchuang Intelligent Equipment Co,. Ltd specializes in developing and manufacturing advanced automation solutions for packaging machinery, serving a wide range of industries with high-quality, customized equipment.

copyright © 粤ICP备2024315457号 Dongguan Shenchuang Intelligent Equipment Co,. Ltd

@2024 Saepack

HOME

PRODUCT

HOME

EXPERICENCE

SERVICE

CONTACT US

Follow us

Contact info

Tel_1

Tel_2

Address

+86-018944711990

+86-013602366642

Henglizhen Tiantoucun

Industrial Zone 2,

Dongguan, China

sales@sae-automtion.com