-

HOME

-

PRODUCT

- Case Packer

- Delta

- Dropdown

- Robot

- Servo

- Sideload

- Teltscospic

- Topload

- TurnableOther

- Palletizer

- cobot

- equipment

- intelligence

- palletdispenser

- robot

- Others

- cartoner

- erector

- sealer

- stapping

- weighter

- metal

-

EXPERIENCE

- kadina

- S418419

- S425426

- S413

- S433434

- S436

- S454

- S501

-

SERVICE

-

CONTACT US

-

HOME

-

PRODUCT

- Case Packer

- Delta

- Dropdown

- Robot

- Servo

- Sideload

- Teltscospic

- Topload

- TurnableOther

- Palletizer

- cobot

- equipment

- intelligence

- palletdispenser

- robot

- Others

- cartoner

- erector

- sealer

- stapping

- weighter

- metal

-

EXPERIENCE

- kadina

- S418419

- S425426

- S413

- S433434

- S436

- S454

- S501

-

SERVICE

-

CONTACT US

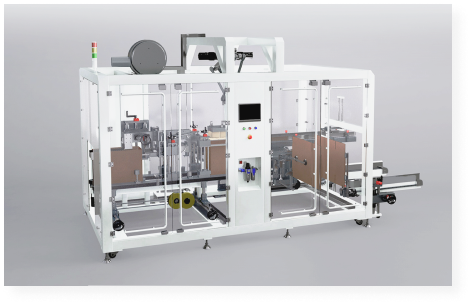

Top-load Case Packer

End of Packing Machine for Fires

Date

[Aug 28th 2021]

[Kadina Industrial]

Client

[Daily Chemical]

industry

Packaging serves a dual purpose: firstly, ensuring products arrive safely and intact at supermarkets, drugstores, and retail outlets. Secondly, it plays a crucial role in attracting consumer attention with appealing aesthetics at the point of sale, particularly in affluent regions like Central and Western Europe.

Display and tray packaging are especially effective in showcasing product brands and enticing purchases, while also providing enhanced shelf stability. Trays can be swiftly set up, ensuring products are immediately retail-ready upon arrival. For home products, packaging must meet the criteria of secure transportation, attractive presentation, and rapid shelf deployment. Flexibility is paramount, given the frequent need for manufacturers to switch between various packaging formats.

In addition to speed and gentle handling, high flexibility is an important criterion. Frequent changes between different packaging formats are part of the daily routine for many manufacturers. Our equipment facilitates seamless adaptation across a wide range of formats, ensuring efficient packaging for medium to large-scale operations.

We choose one standard case as reference for you. Customer requirements are as follows:

Detailed Requirements

Specific Parameters

Product type

Box

Incoming speed

60 bags per min

Packing requirement

Carton dimensions

1*5*2 Layer/1*5*4 Layer

550*220*340mm 550*220*190mm

Tip: Product dimensions and packaging speed are customizable, tailored according to customer requirements.

Main Configuration

Suitable for boxes, cans, bottles, bags and other products, it is controlled by servo motors, occupies a small area, and is easy to maintain and intervene immediately.

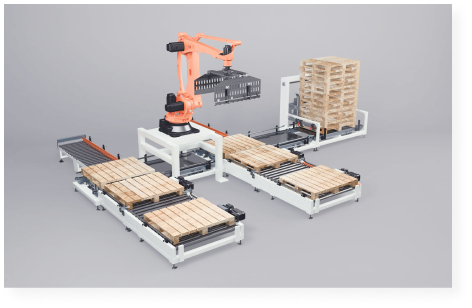

The design of the equipment enables the robot to concentrate exclusively on stacking incoming products. Other tasks like dispensing pallets are automatically managed by separate equipment.

Robot Palletizer

It supports packaging line operations with packaging machinery, facilitating automated pallet staging and supply distribution, significantly improving efficiency and saving on labor resources.

Pallets Dispenser

Dongguan Shenchuang Intelligent Equipment Co,. Ltd specializes in developing and manufacturing advanced automation solutions for packaging machinery, serving a wide range of industries with high-quality, customized equipment.

copyright © 粤ICP备2024315457号 Dongguan Shenchuang Intelligent Equipment Co,. Ltd

@2024 Saepack

HOME

PRODUCT

HOME

EXPERICENCE

SERVICE

CONTACT US

Follow us

Contact info

Tel_1

Tel_2

Address

+86-018944711990

+86-013602366642

Henglizhen Tiantoucun

Industrial Zone 2,

Dongguan, China

sales@sae-automtion.com